New terminal with special connections, 1.5 mm²

VPC.2/S is a 1.5 mm² screw terminal block for female connectors pitch 5.08 mm with aligned outputs.

€79,80 + VAT

Temporarily not available for online purchase. Contact our sales department.

Temporarily not available for online purchase. Contact our sales department.

| Series | HVTE-CHTE |

|---|---|

| Code | HVT910 |

| Type | CHTE.2D |

| HS code | 85389099 |

| Colour | Yellow-green |

| TECHNICAL FEATURES | |

| Function/Type | Female earth connector |

| Rated cross-section | 2.5 mm² |

| Connecting capacity | |

| Flexible wire | 0.2-4 mm² |

| Rigid wire | 0.2-4 mm² |

| Wire with ferrule - ferrule type | 2.5 mm² – WP25/14 |

| Electrical characteristics according to IEC EN standard | |

| Maximum current (rated cross-section) | – |

| Caliber | A3 |

| Electrical characteristics according to UL Standard | |

| Maximum voltage AC/DC | 600 V |

| Maximum current (rated cross-section) | – |

| Section (min-max) | 28-12 (AWG) |

| Electrical characteristics according to ATEX directive and IEC Ex standard | |

| Maximum voltage AC/DC | – |

| Insulation stripping length | 10 mm |

| Widht (pitch) | 5.2 mm |

| Length | 58 mm (1) |

| Height mounted on TH35-7.5/TH35-15/G32 | 67 / 75 / – mm (1) |

| Insulation material temperature index (EN 60216-1) | 130 °C |

| Plastic material | Polyamide UL94V-0 |

| ACCESSORIES | |

| End section | |

| Grey | CHP.2D/PT/GR (cod. HVP911GR) |

| Blue | – |

| Thickness | 2.5 mm |

| Cross-connection | |

| Model A) | PTC/03/… (cod. PTC03…) |

| Model B) | PTP/03/… (cod. PTC03…) |

| Rated current carrying capacity IEC/ATEX | 24 A |

| Cross-connection identification strip | PTC/SP (cod. PTC0990) |

| Coloured partition plate | DFH/1/R (cod. DH01R) |

| Cross-connection barrier | ‒ |

| Test plug | SDD/1 (cod. DD001) |

| Modular test plug | SDH/5 (cod. DH005) |

| End section for modular test plug | SH5/PT (cod. DH501) |

| Marking | |

| Single marking tag | CNU/8/51 (cod. NU0851S) – CNU/10/51 (cod. NU1051S) |

| Single marking tag for pitch insertion | CNU/8/51 (cod. NU0851S) |

| End bracket | |

| TH35 screw type | – |

| TH35 snap-fit type | – |

| TH35 and G32 snap-fit type | – |

| DIN rail according to IEC 60715/TH35 | – |

| APPROVALS AND MARKINGS |    |

For further information see PDF catalog

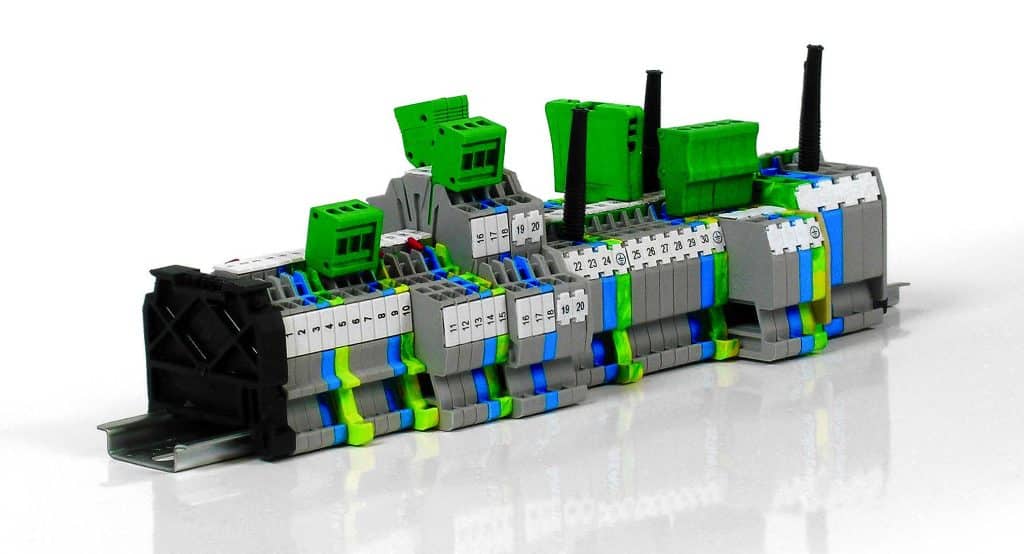

For the creation of high harness volumes, for conductors from 0.2 to 25 mm2 and reduced current intensity values, CABUR proposes its range of spring-clamp terminal blocks.

To protect the clamping system, the insulating body includes a stopper which prevents the spring from going beyond the threshold of its elastic field, if is activated by inexpert hands.

Adequate sizing of the wire introduction chamber, responding to the requirements of the IEC 60947-1 Standard, guarantees insertion of any type of conductor of the nominal size, also butted with a terminal.

The connection that results from this, in relation to the technology adopted, has the maximum reliability and safety thanks to the quality of the materials used and to the particular conformation of the components needed for the purpose, avoiding damage to the strands of the conductors in the presence of unprepared flexible wires.

The connection that results from this, in relation to the technology adopted, has the maximum reliability and safety thanks to the quality of the materials used and to the particular conformation of the components needed for the purpose, avoiding damage to the strands of the conductors in the presence of unprepared flexible wires.

The wire entry is perpendicular to the installation surface determining a further reduction of times and costs of the wiring operations above all where the spaces are particularly limited. To connect together several contiguous elements, a practical and safe bridging system is available.

Terminal blocks with rated cross-sections of between 1.5 and 16 mm2 have the possibility of being connected together in the most disparate ways thanks to our exclusive “Easy Bridge” rapid connection system (PTC), which combines efficiency, rapidity and flexibility providing at the same time a exceptional economic result; these characteristics together with the resulting IPXXB intrinsic installation without the aid of further insulation protections (of wires, terminal blocks and parallel connections), guarantees better connectivity than that offered by the competitors.

MARKING SYSTEMS

In our marking system the same multiple numbering strip (SHZ) can be inserted on the sides of the terminal block or in the specific seats present in the upper part of the terminal block itself.

In our marking system the same multiple numbering strip (SHZ) can be inserted on the sides of the terminal block or in the specific seats present in the upper part of the terminal block itself.

This means easy identification of each terminal block from every viewing angle within the electrical panel. The numbering can be done also with the single standard-type CNU/8 tags.

This means easy identification of each terminal block from every viewing angle within the electrical panel. The numbering can be done also with the single standard-type CNU/8 tags.

VPC.2/S is a 1.5 mm² screw terminal block for female connectors pitch 5.08 mm with aligned outputs.

The new “Easy Bridge Plus” multi-pole cross connections for CBC.6 terminal blocks are available in red or blue colours for instant visibility. If needed, the upper surface can be marked with a permanent marker to highlight the presence of the pole and of the electrical connection with the underlying terminal block in pole skipping cross connection configurations.

The new products extend the range of Cabur’s Easy Fast Connection (EFC) series, spring clamp terminal blocks with push-in technology.

Copyright © Cabur srl Sede legale Località isola Grande, 45 – 17041 Altare (SV) – Italia – Tel. 019-589991 – Fax 019-58999233 – E-mail: info@cabur.it

Cap. Sociale: €2.000.000 Int. versato – Reg. Soc. Trib. Savona N° 4635 – C.C.I.A.A. N° 27269- Export N° SV 000532 – Iscrizione al Registro AEE n. IT18050000010376 – P.IVA e Cod. Fisc.: 00100760099

DISCLAIMER Cabur Srl may change and update any document available online without any obligation to inform users. Only cabur.it and cabur.eu domains are registered and maintained by Cabur srl. Cabur has no responsibility for contents published on sites under the same name, with different extensions from .it and .eu

To provide the best experiences, we and our partners use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us and our partners to process personal data such as browsing behavior or unique IDs on this site and show (non-) personalized ads. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Click below to consent to the above or make granular choices. Your choices will be applied to this site only. You can change your settings at any time, including withdrawing your consent, by using the toggles on the Cookie Policy, or by clicking on the manage consent button at the bottom of the screen.

for technical support

+39 019 58999.219 customercare@cabur.it

for commercial support

+39 019 58999.609 vendite@cabur.it

from monday to friday 8:30-12:30 13:00-17:00