E-mobility and Renewable Energy Solutions catalogue 2025

E-mobility and Renewable Energy solutions catalogue: an edition renewed even in name!

€360,00 + VAT

In stock

In stock

For further information see PDF catalog

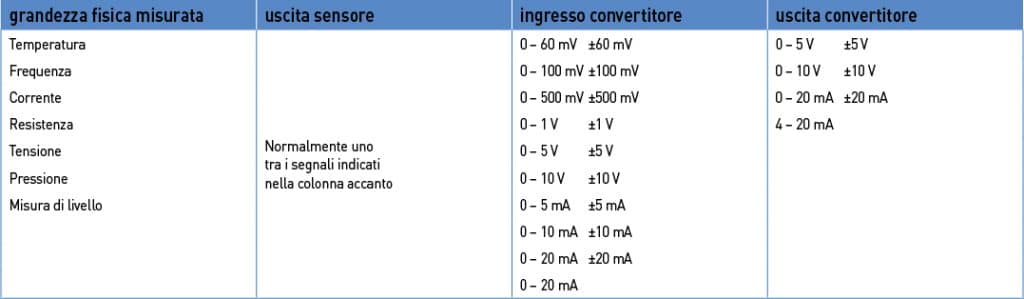

They convert electrical signals generated by sensors which take physical measure-ments such as temperature (thermocouples and PT100 resistance thermometers), frequency (proximity, contacts, photocells), current (TA, Hall sensors), resistance (potentiometers), voltage, pressure, level, etc. into standardised electrical signals, adapting them to PLC, DCS and industrial PC (control) outputs, or they convert a given analogue signal into a different one, adapting it to control inputs/outputs or allowing for long-distance signal transmission without interference by means of galvanic separation (fig. 1).

Adaptation between sensor output signal and control input signal

Long-distance signal transmission

Voltage signals can reach a max. distance of 10-20 m, beyond which they lose reliability and become highly sensitive to induced and ground-derived interference, therefore in order to transmit to distances beyond 20 m a voltage signal must be converted into a current signal and galvanically separated (fig. 2).

Current signals can surpass a transmission distance of 300 m and are less sensitive to induced interference. The long-distance transmission of a current signal requires galvanic separation.

Galvanic signal separation (signal isolation):

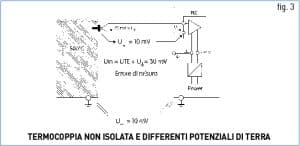

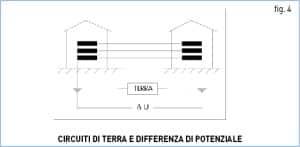

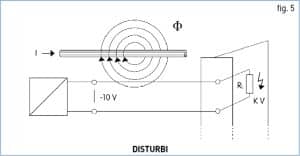

Galvanic separation is necessary when:

Galvanic separation is necessary when:

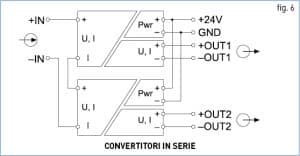

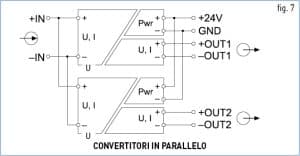

Connection of analogue converters in series and in parallel

Connection of analogue converters in series and in parallel

In case of voltage signals, the converter input will be connected in parallel (fig. 7

In case of voltage signals, the converter input will be connected in parallel (fig. 7

E-mobility and Renewable Energy solutions catalogue: an edition renewed even in name!

From 13 to 15 May, Cabur will be waiting for you at Fiere di Parma, hall 5 stand L 043.

The Cabur Marking Pro XT software update 2.7.2.1 is online and includes, among other things, important new features for modular strips.

Copyright © Cabur srl Sede legale Località isola Grande, 45 – 17041 Altare (SV) – Italia – Tel. 019-589991 – Fax 019-58999233 – E-mail: info@cabur.it

Cap. Sociale: €2.000.000 Int. versato – Reg. Soc. Trib. Savona N° 4635 – C.C.I.A.A. N° 27269- Export N° SV 000532 – Iscrizione al Registro AEE n. IT18050000010376 – P.IVA e Cod. Fisc.: 00100760099

DISCLAIMER Cabur Srl may change and update any document available online without any obligation to inform users. Only cabur.it and cabur.eu domains are registered and maintained by Cabur srl. Cabur has no responsibility for contents published on sites under the same name, with different extensions from .it and .eu

To provide the best experiences, we and our partners use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us and our partners to process personal data such as browsing behavior or unique IDs on this site and show (non-) personalized ads. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Click below to consent to the above or make granular choices. Your choices will be applied to this site only. You can change your settings at any time, including withdrawing your consent, by using the toggles on the Cookie Policy, or by clicking on the manage consent button at the bottom of the screen.

for technical support

+39 019 58999.219 customercare@cabur.it

for commercial support

+39 019 58999.609 vendite@cabur.it

from monday to friday 8:30-12:30 13:00-17:00